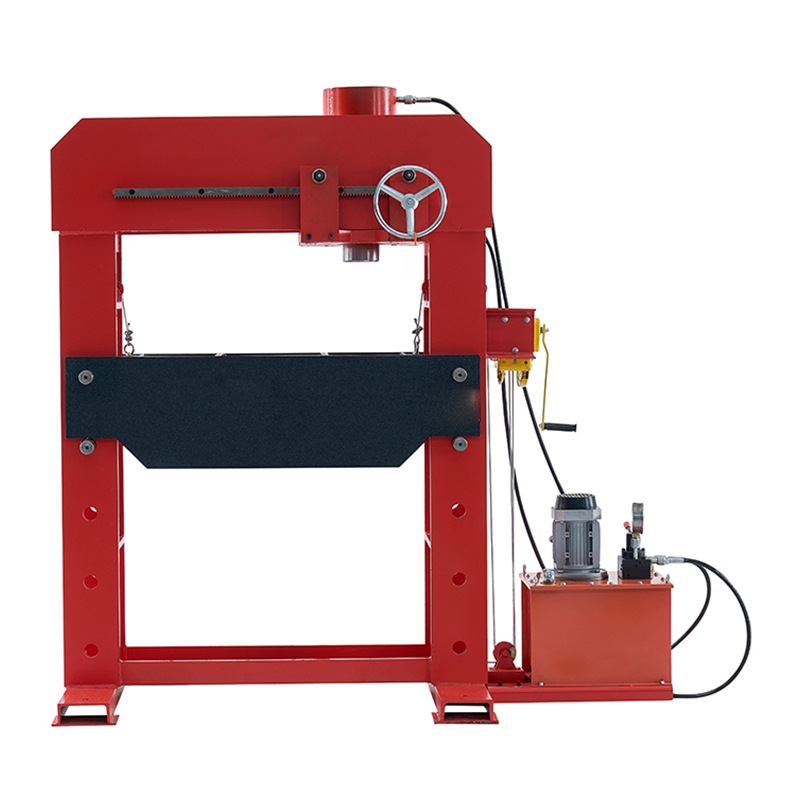

Features

- A pressing capacity of 200 tons suitable for punching, flattening/bending metals, dismantling gears/liners/bearings, etc.

- Dual hydraulic cylinders operate pneumatically and manually, allowing for complete control, stable plunger speed, and smooth overall workflow.

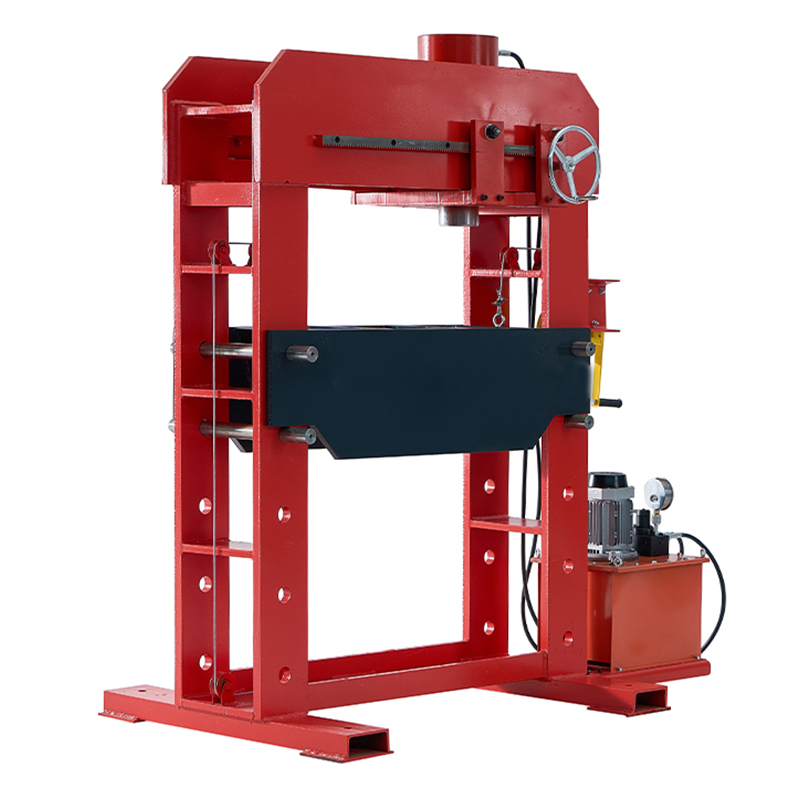

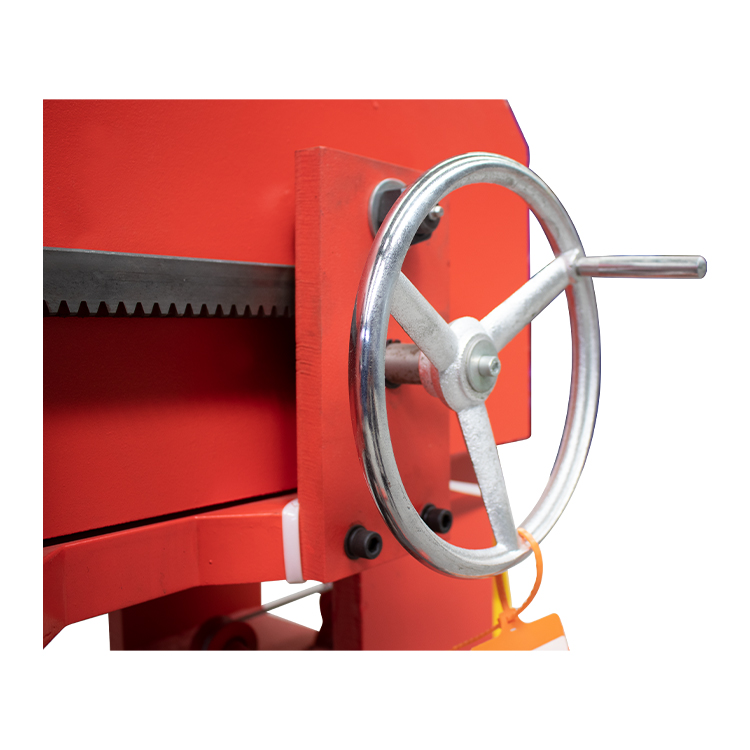

- Left and right sliding block motion provides multiple working positions, while dual springs assist in piston rod retraction.

- The sturdy and fully welded H-shaped frame enhances rigidity and durability, suitable for long-term commercial use in any workshop environment.

- Oil level gauges in both US and metric tons allow for accurate and consistent pressure monitoring during operation.

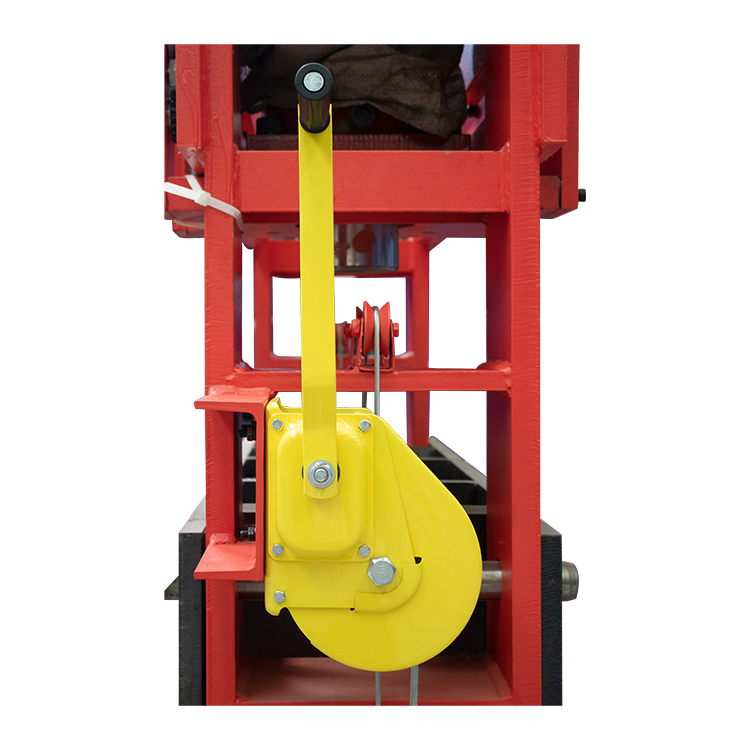

- Steel cable crank winch with slip-resistant safety clutch provides ergonomic relief by eliminating excessive bending and allowing easy up/down of the press bed.

- Specifically designed for handling demanding tasks under high pressure; equipped with overload pressure relief valve to prevent exceeding machine capacity.

Specifications

| Specification Category | Specific Details |

|---|---|

| Machine Dimensions | Length × Width × Height: 59” × 43.3” × 78.7” |

| Internal Frame Size | – Width: 13-3/4”

– Length: 39-3/8” |

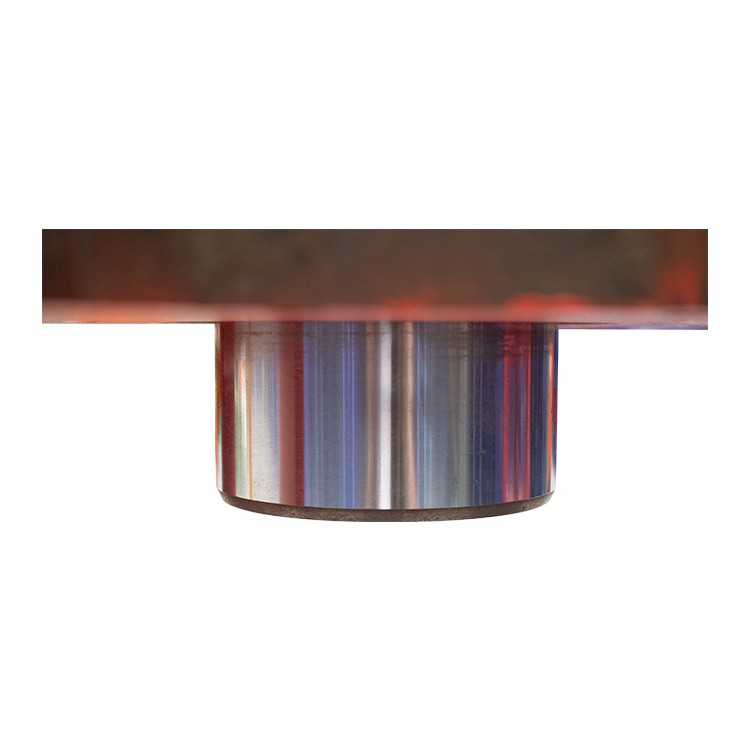

| Ram & Plunger Parameters | – Ram Stroke: 13-3/4”

– Plunger Diameter: 4-5/8” – Plunger Lateral Movement: 13” – Plunger Head Diameter: 3-7/8” |

| Protective & Opening Sizes | – Protective Cover (Width × Height): 36“ × 23”

– Operable Carriage Opening (Length × Width): 34“ × 16” |

| Carriage Specification | Carriage Pin Diameter: 2-1/4” |

| Pressure Parameters | – Exhaust Pressure: 105-115%

– Maximum Pump Pressure: 8500 PSI – Pressure Gauge Accuracy: +/- 2.5% |

| Workpiece Limit | Maximum Allowable Workpiece Height: 37” |